2. Development of BMP Cost-Effectiveness-Values

Table

0.

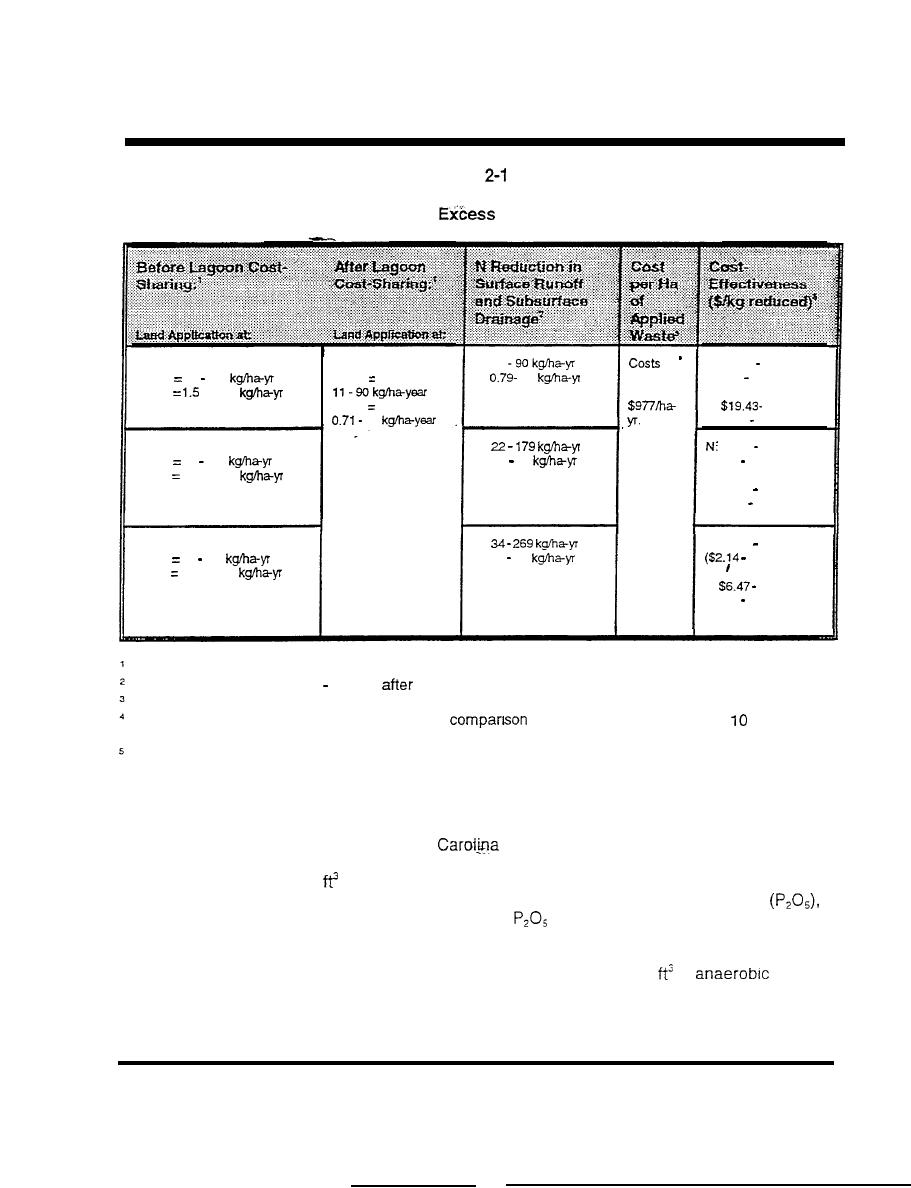

Cost-Effectiveness of Anaerobic Lagoons Relative to Land Application

Rates

at

N: 11

Agronomic Rates

N: .86 21.05

2x Agronomic Rates

range from

(.44 .86)'

N loss

P:

22

N loss 22 179

5 to

P loss

to 44.8

P loss

5298.30

P:

22

(.76 4.94)

N:

.43 .52

3x Agronomic Rates

P: 1.5 45

(2 .93)

N loss 34 269

P loss 2.2 to 67.2

P: .71 8.20

(.88 9.40)

N:

N:

||content||

.62 .02

4x Agronomic Rates

P: 22

67

.29)

N loss 45 359

P loss 2.9 to 89.7

P:

7.63

(.57 142.47)

From Table 2-4.

(losses before cost-sharing) (losses

cost-sharing).

From Table 2-9.

The numbers in parentheses are presented for

purposes and are based on a

year life

span instead of the SCS life span of 20 years.

See Appendix 6 for calculation details.

a database of manure, lagoon sludge, and lagoon liquid characterization from

North Carolina farms (North

Agricultural Extension Service, 1990).

Based on these data, the averagenitrogen (TKN) reduction for a swine waste

of treatment volume per pound of live weight is 73 percent or

lagoon with 1

0.374 lb N per thousand pounds live weight per day. For total phosphate

the reduction is 69 percent or 0.272 lb

per thousand pounds of live weight

per day.

For poultry waste lagoons, the SCS guidelines require 2.5

of

lagoon

treatment volume per pound of live weight (R. Hansard, 1994). Based on the NC

Extension data mentioned above, the nitrogen (TKN) reduction for this type of

lagoon is 77 percent or 0.658 lb N per thousand pounds of live bird weight per

21

Previous Page

Previous Page