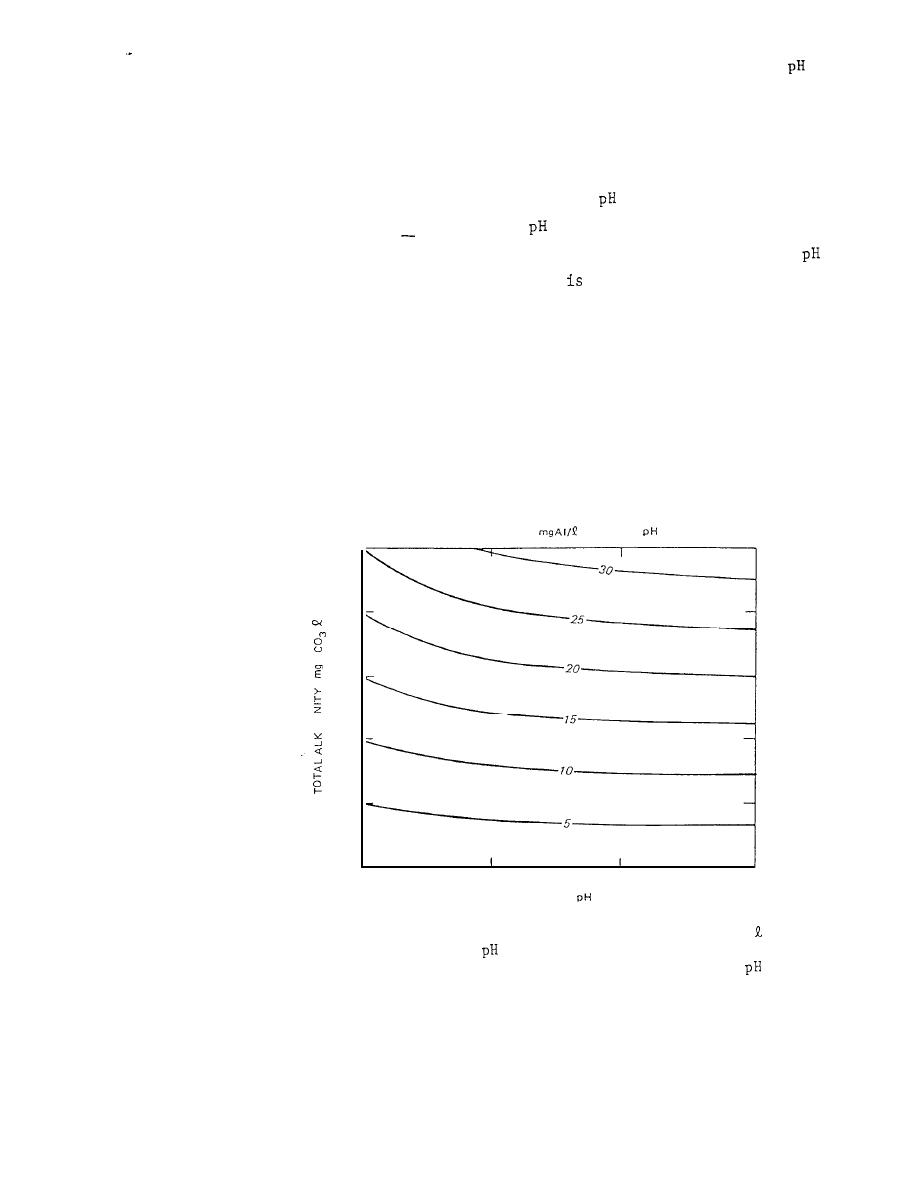

and alka-

for dose determination can also be developed from a knowledge of

linity of each stratum and use of the nomograph from Kennedy and Cooke (1982)

(see Figure 7).

For dose determination, a vertical series of water samples is obtained

and alkalinity is determined.

Then, other water samples from the same depths

are titrated with stock solutions of alum to

6.0.

The relation between the

aluminum dose and the alkalinity and

is then used to obtain the maximum

dose for any reservoir alkalinity over the range of alkalinity and

tested.

The maximum dose for each depth interval

calculated from the titration and

water volume for that depth interval, and these are summed to produce the

total dose for the reservoir, or section of the reservoir.

Accuracy in treat-

ing the reservoir is obtained by dividing the treatment areas, or the reser-

voir, into zones marked by buoys.

The volume and alkalinities in each of the

zones are measured, and the amount of alum is then determined.

By dividing

the reservoir into sections, an overdose to shallow areas or an underdose to

deep areas is avoided.

ALUMINUM DOSE,

TO OBTAIN

6.0

250

200

3

150

3

4

100

50

0

7.5

6.5

7.0

8.0

INITIAL

-1

)

Figure 7. Estimated aluminum sulfate dose (mg Al

required to obtain

6 (i.e., "maximum dose") in

treated water of varying initial alkalinity and

(from Kennedy and Cooke 1982)

50

Previous Page

Previous Page